- News

- Game shooting

- Fly fishing

- Big game

- Sporting art

- Guest editors

- Gear

- Competitions

- More

-

-

More

-

- No posts selected.

-

-

-

-

★ Win a Schöffel Country shooting coat for everyone in your syndicate worth up to £6,000! Enter here ★

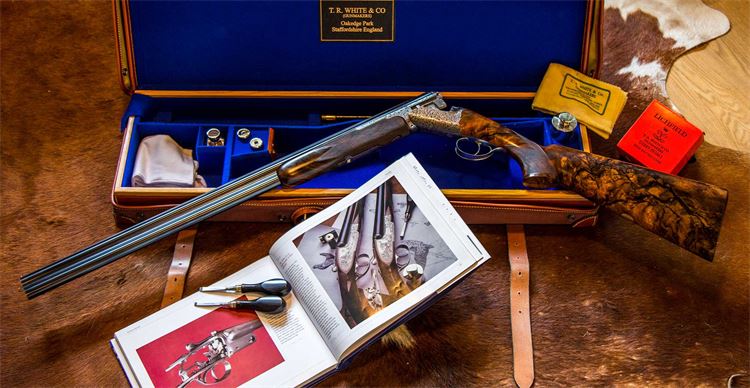

T. R. White & Co. Gunmakers

A visit to the family-run T. R. White & Co. gunmakers in Staffordshire who have big plans for the future.

Whatever the industry, whatever your background, venturing away from a secure income as an employee to set up your own business takes some serious courage. Of course, only time will tell if the risk is worth the reward, but as a 30-year-old, married with two young children, most would let their dreams fall by the wayside. This scenario was not going to stop Staffordshire-based Tony White from starting up his own gunmaking firm in 1989, though.

“Without doubt, the biggest challenge I faced when going it alone was the uncertainty of it all,” admitted Tony as we took up seats in the quaint office adjacent to his workshop on the Wolseley Estate in Staffordshire. “The 1960s to ’80s was a tough time for the industry due to inflation, with many firms having to scale down operations, sell up or shut down completely,” he explained. Even W&C Scott – where Tony had served his apprenticeship and worked for 15 years – was bought out by the Holland & Holland group.

“I was stocking guns for Westley Richards & Co. (W. R. & Co.) at the time, and I asked Simon Clode – who had joined the firm in the mid 1980s – what his thoughts were about me going it alone. Astonishingly, his response was that I should certainly give it a shot, and that he’d guarantee me a year of work if I did!”

Simon’s offer – akin to Bentley commissioning a young mechanic to craft their Continental engines – was something that could not be refused, and provided the confidence boost that Tony needed. He proceeded to set up in a small premises near his home and began work under the T. R. White name in the same year.

“Initially, the bulk of my time was spent stocking guns for W. R. & Co., but I also serviced, repaired and restored older guns,” Tony continued. During his apprenticeship, he was, quite unusually, afforded the chance to get involved with all stages of gunmaking, working with both metal and wooden components, rather than focusing on just one element such as actions, barrels or stocks.

“After a year or so, I’d managed to develop a steady clientele, and I was able to entice Ted Atkinson to join me on a part-time basis. Ted was my mentor and worked for W. R. & Co. for many years, specialising in jointing and action making,” he added. In 1991, the duo finally completed their very first gun together – a 28 bore side-by-side game gun with the T. R. White & Co. name engraved on the sideplate. “It was a fantastic achievement and one of the proudest highlights of my career. In today’s day and age it is hard to leave your mark on anything, but our guns are built to stand the test of time.”

For the next four years, Tony and Ted continued to operate from the same location, gaining more loyal clients and a sound reputation. But to realise their collective dream of establishing themselves as makers of fine English guns, they would need to expand and take on more work. And so, in 1995, Tony took the opportunity to relocate the workshop to premises they still occupy to this day. As a result, Ted was able to join Tony on a full-time basis.

To say that together they have realised their dream would be an understatement. Twenty-three years on, the business has even patented their own design which features interlocking sears that prevent the gun discharging if dropped, and have completed over 100 bespoke shotguns of their own design, with each and every example being crafted with the same enthusiasm, time and attention to detail as the first.

A small business in a growing world

Today, in the age of instant everything, small businesses relying on traditional skills face new challenges. CNC manufactured, laser-engraved guns, for example, are improving in quality and popularity, and are available at a fraction of the price of hand-built guns. And then there is online marketing, a necessity in all industries which is constantly changing.

Gladly, taking risks of their own to follow in their father’s footsteps, Tony’s son Matthew and daughter Charlotte are key members of the new business model and the foundations of its future. Four years ago, Matthew left a full-time position in London at Holland & Holland – which he had secured for eight years after completing his training with them – to join the small family business in the Midlands. “It has been great to have him back here working alongside Ted and me,” said Tony. “The experience he gained there was invaluable, and probably the best thing he could have done for his career. Not only has he successfully made his own mark on our guns, but he has even shared some of what he has learnt with our youngest recruit, Brad Jordan, who is helping us out during the week between days at college.

“And then Charlotte has been highly influential to the business outside of the workshop, looking after the marketing and retail side of things,” Tony told me. Since she joined in 2014, Charlotte has taken it upon herself to set up and run the country store and coffee shop – situated on the opposite side of the courtyard – with the help of Rebecca Hemmings and Callum McComisky. Here they sell clothing, accessories, new and used shotguns, and run the website and social media. “With the workshop’s current capacity, staying up to date with the modern world simply wouldn’t be achievable without Charlotte,” said Tony, “and it allows us to focus solely on making, repairing, restoring and servicing guns.

“So, when the time is right, I’ll be happy to know the business is in capable hands,” he smiled. “And I now have a grandson, Harry. Who knows, maybe in 30 years’ time the business may be taken over by another generation of Whites!”

About the guns

As we finished the bulk of the interview, I followed Tony into the workshop where I was finally able to see the guns for myself. It was every bit what you would expect a traditional gunmakers to be – files, screwdrivers, pliers and tools of all shapes and sizes were spread across the desks and shelves, vices were well worn, and under each lamp a different component was being made. “We can each work on most elements,” Tony explained, as I was introduced to the trio of workers. “But Ted and Matthew tend to focus on barrels and actions, I specialise in making stocks and fore-ends, and Brad helps out on various stages but loves to work with wood most.

“This is a new round-action design we have been working on for a client,” he continued as he lifted a stunning 12 bore over-under from his bench and handed it to me. The first thing that caught my eye was the beautiful grain in the exhibition-quality walnut, followed by the deep engraving of the metalwork by Peter Spode – a man well-known for his work on Westley Richards guns and rifles – which shimmered in the artificial light.

I could have marvelled at this best English gun all afternoon, but I had to let it leave my grasp as Tony handed me another – this time a side-by-side, a 12 bore boxlock ejector featuring darker wood, case colour hardened metalwork, and an older, more traditional style of scroll engraving. It, too, was a real looker. “Believe it or not,” Tony added, “we built and sold this gun over 20 years ago! We had heard it was going on the market and made an offer for it as soon as we could. Matthew now uses it for all of his clay and game shooting.”

Though neither gun was built to fit my specifications, they both felt remarkably well balanced and were a pleasure to handle – something best English guns are known for. “Yes, we are very creative with our designs and the aesthetics are incredibly important, but understanding how a gun should be balanced for its primary purpose is paramount. All of us here shoot game, so we have a good knowledge of how a gun should feel,” Tony stated.

To achieve this perfect balance, the barrels must be struck until they are very fine, making them suitable only for lead-shot cartridges. By contrast, the barrel walls of mass-produced guns remain thicker so that they can withstand harder shot like steel, but they do not handle like best guns. “Should there be new legislation on cartridge production, our sector of the gun trade – comprising those who still make guns by hand – could face the biggest challenge yet,” admitted Tony.

Attention to detail and delivering exactly what the client orders is of high priority. The company work on a maximum of six guns at any one time, and each could be completely different to the next. One gun that was in construction when I visited featured a heavily engraved sideplate, bottom strap and pistol grip cap, plus a very long fore-end with inlaid metal details. In contrast, the emphasis of another gun was on the grain and chequering of the walnut.

It will come as no surprise that each gun will take approximately 18–24 months to complete, with pairs taking over two and a half years. Certainly, to have a gun of such quality comes at a price, and to have your very own with the T. R. White & Co. mark will set you back a minimum of £35,000, but when you consider the expertise, craftsmanship and customer service that comes with investing in this family business, the cost is well worth it.

Related Articles

Get the latest news delivered direct to your door

Subscribe to Fieldsports Journal

Elevate your experience in the field with a subscription to Fieldsports Journal, the premium publication for passionate country sports enthusiasts. This bi-monthly journal delivers unparalleled coverage of game shooting, fishing and big game across the UK and beyond.

Each issue offers a stunning collection of in-depth features, expert opinions and world-class photography, all presented in a timeless yet contemporary design.

Save 10% on shop price when you subscribe, with a choice of packages that work for you. Choose from Print & Digital or Digital only with each journal delivered directly to your door or via the app every other month, plus access to past issues with the digital back issue library.