Browning B15 Beauchamp

Marcus Janssen is very impressed with the Browning B15 Beauchamp over-under.

There can’t be many gunmaking companies with a more confusing history than Browning. They’re an iconic American brand, and yet almost all of their guns are manufactured in Europe and Japan. In order to understand why this is, one must go back to the beginning.

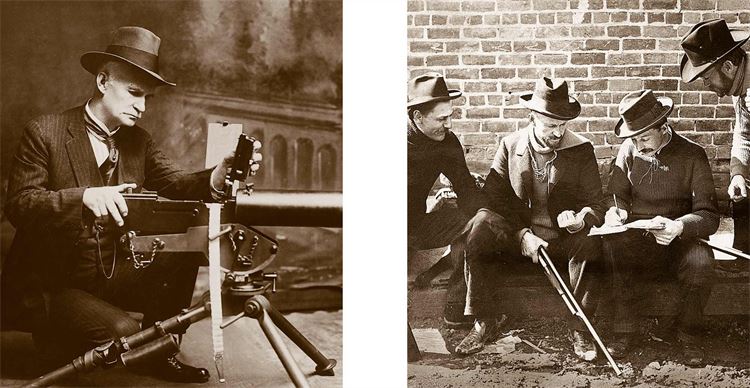

The company was founded in 1878 to market the sporting (non-military) designs of John Moses Browning, an American gunmaking genius and one of the world’s most prolific firearms inventors (he is credited with 128 US patents). But instead of manufacturing his designs under his own name, he tended to license them out to other firms such as Winchester, Colt and Remington. Indeed, John Browning was the brains behind several of Winchester and Colt’s most iconic and best-selling firearms.

But it is another company altogether with which the Browning name is most directly affiliated – Fabrique National d’Hevrstal (FN) of Belgium. In 1897, almost 20 years after Browning Arms was founded, the board of FN sent sales manager Hart O. Berg to the United States on a fact-finding mission into the advances that had been made in bicycle manufacturing.

Whilst in the States, Berg met two arms manufacturers, John Moses Browning and his brother Mathew. John, whose ingenuity and creative spirit had earned him a reputation as one of the most innovative minds in the American gunmaking industry, had just taken out a patent for a 7.65mm blowback-operated automatic pistol which Berg immediately took an interest in.

Browning duly offered the manufacturing license for the pistol to FN which was presented to the board on June 19 that year, and the contract was signed on July 27.

Thereafter, the directors of FN wasted no time in obtaining the rights to manufacture most of John Browning’s new firearms and components as and when he invented them. But it was in 1907 that, at FN’s request, John granted the right to use his surname as a trademark. He never gave the same permission to any of the large American companies that had commercialised his first inventions.

In the years that followed, the popularity of firearms developed by Browning and manufactured by FN would continue to increase, both in Europe and America. The sales figures provide convincing proof of this, especially with regard to pistols. From 1899 to 1906, a quarter of a million pistols were sold. In 1908, the total reached 500,000 and in July 1912, the millionth pistol was assembled in Herstal. Of course, the First World War changed everything. Germany requisitioned much of FN’s factory machinery and equipment, and production of Browning firearms ground to a halt.

But shortly after the war, John returned to Herstal where, in collaboration with staff from FN, he resumed his research and inventions. Among these were a .22 rifle and a hunting shotgun with superimposed barrels. The latter was in the prototype stage, having been designed three years earlier, but, ultimately, it was destined to become the world-renowned B25 ‘Superposed’ that is still in production today.

But before he was happy to launch his new B25 Superposed, John Browning wanted to improve its operation and to adapt it – as far as the techniques of the time would allow – so that it could be mass produced at a competitive price. Sadly, he was still perfecting it in 1926 when he died in his office at Fabrique National. He had made approximately 61 Atlantic crossings over the previous 30 years.

The completion of the B25 therefore fell to John’s son, Val Allen Browning, who finally launched the B25 in 1931, having acquired a number of further patents including one for the B25’s single trigger mechanism. Thanks to the combined efforts of father and son, as well as the technicians and gunmakers of Herstal, the Browning B25 over-under shotgun went on to become a 20th century benchmark in the manufacturing of game guns, with almost 400,000 being produced in Belgium over a 45-year period.

The B25 action

Mark Crudgington takes a closer look at the design and evolution of the B25.

John Moses Browning’s early ventures of single-shot, pump, lever-action and semi-automatic shotguns and rifles had a somewhat ‘agricultural’ look and feel about them. However, look and feel are not everything, a tool has to work, and all of the Browning designs did that.

Once production was moved to Fabrique National in Herstal, Belgium, there is a noticeable aesthetic improvement of the finished products of his designs. Indeed, it could be argued that the B25 Superposed could not have become what it has without some European influence. And it owes more than a nod to British gun design.

The B25’s fixed sliding fore-end can be traced back to the Ellis and Wilkinson patent of 1877, the cocking link between fore-end and cocking bar is loosely based upon W. W. Greener’s patent of 1880, and the cocking bar itself is adapted from Bentley and Baker’s patent of 1883.

Browning was able to combine these designs into a compact over-under gun. The barrels – the only parts of the design that still require a great deal of skilled craftsman’s input to the basic build – still use the classic under-lumps of the standard side-by-side design, using the forward edges of the split rear lump to draw up against the forward faces of the deep slots in the underside of this strong, heavier than necessary action. This, combined with a full-width locking bolt held in place by the whole of the standing breech and its thick side walls, gives the design immense strength, indeed it is one of the strongest designs ever.

By making the two tangs at the rear of the action rigid (by screwing them together and using a stock bolt to secure the action to the stock), a firm, unmoving platform was given to the very simple (and in the 91 subsequent years), much-copied inertia single trigger. Using coil springs in place of English or European gun’s leaf springs for the main ejector, sear and trigger springs, resulted in a huge saving in cost combined with a spring that will work even if broken.

The over-slung sears, whilst utilising the given space in the action, actually give poor and draggy trigger-pulls that cannot be improved to the quality of a best gun.

The stock bolt allows for pre-machined stocks to be easily fitted with limited input of a skilled gun stocker, thus keeping costs down.

With Fabrique National’s machining capabilities, Browning made his design as machine friendly as possible, meaning all the handwork involved was focussed on minimal fitting and finishing.

This can be seen in the early B25s that are lumpy, heavy, boxy and frankly, as I have said before, agricultural. After John Moses Browning’s death, his son Val improved the single trigger and, along with the artisans at Fabrique National, restyled and reshaped the barrels, fore-end and action, and used much more skilled handwork from Herstal’s craftsmen until the B25 reached its aesthetic zenith in the 1970s.

There can’t be many gunmaking companies with a more confusing history than Browning. They’re an iconic American brand, and yet almost all of their guns are manufactured in Europe and Japan. In order to understand why this is, one must go back to the beginning.

The company was founded in 1878 to market the sporting (non-military) designs of John Moses Browning, an American gunmaking genius and one of the world’s most prolific firearms inventors (he is credited with 128 US patents). But instead of manufacturing his designs under his own name, he tended to license them out to other firms such as Winchester, Colt and Remington. Indeed, John Browning was the brains behind several of Winchester and Colt’s most iconic and best-selling firearms.

But it is another company altogether with which the Browning name is most directly affiliated – Fabrique National d’Herstal (FN) of Belgium. In 1897, almost 20 years after Browning Arms was founded, the board of FN sent sales manager Hart O. Berg to the United States on a fact-finding mission into the advances that had been made in bicycle manufacturing.

Whilst in the States, Berg met two arms manufacturers, John Moses Browning and his brother Mathew. John, whose ingenuity and creative spirit had earned him a reputation as one of the most innovative minds in the American gunmaking industry, had just taken out a patent for a 7.65mm blowback-operated automatic pistol which Berg immediately took an interest in.

Browning duly offered the manufacturing license for the pistol to FN which was presented to the board on June 19 that year, and the contract was signed on July 27.

Thereafter, the directors of FN wasted no time in obtaining the rights to manufacture most of John Browning’s new firearms and components as and when he invented them. But it was in 1907 that, at FN’s request, John granted the right to use his surname as a trademark. He never gave the same permission to any of the large American companies that had commercialised his first inventions.

In the years that followed, the popularity of firearms developed by Browning and manufactured by FN would continue to increase, both in Europe and America. The sales figures provide convincing proof of this, especially with regard to pistols. From 1899 to 1906, a quarter of a million pistols were sold. In 1908, the total reached 500,000 and in July 1912, the millionth pistol was assembled in Herstal. Of course, the First World War changed everything. Germany requisitioned much of FN’s factory machinery and equipment, and production of Browning firearms ground to a halt.

But shortly after the war, John returned to Herstal where, in collaboration with staff from FN, he resumed his research and inventions. Among these were a .22 rifle and a hunting shotgun with superimposed barrels. The latter was in the prototype stage, having been designed three years earlier, but, ultimately, it was destined to become the world-renowned B25 ‘Superposed’ that is still in production today.

But before he was happy to launch his new B25 Superposed, John Browning wanted to improve its operation and to adapt it – as far as the techniques of the time would allow – so that it could be mass produced at a competitive price. Sadly, he was still perfecting it in 1926 when he died in his office at Fabrique National. He had made approximately 61 Atlantic crossings over the previous 30 years.

The completion of the B25 therefore fell to John’s son, Val Allen Browning, who finally launched the B25 in 1931, having acquired a number of further patents including one for the B25’s single trigger mechanism. Thanks to the combined efforts of father and son, as well as the technicians and gunmakers of Herstal, the Browning B25 over-under shotgun went on to become a 20th century benchmark in the manufacturing of game guns, with almost 400,000 being produced in Belgium over a 45-year period.

Browning today

While FN (who, since 1977, have owned Browning outright) shifted the production of all mass-produced Browning guns and rifles to Japan (over-under shotguns) and Portugal (semi-auto shotguns and bolt action rifles) in the 1970s, the B25 has continued to be made in Belgium by master craftsmen, with each one being made to order. But of course anything bespoke comes at a price; B25s retail at between £13,600 and £50,000, with only 40–50 being made per year.

Therefore, as is the case with all handmade guns, the B25 is simply out of reach for the majority of sportsmen and women. Which is why Browning launched the B15 Beauchamp last year.

Conceived by the team at the Browning Custom Shop in Liege (recently rebranded as the John M. Browning Collection to include the B25 and B15), the B15 Beauchamp is something of a cross or halfway-house between a fully custom-made B25 and a mass-produced B725 (Browning’s newest mass-produced over-under).

Although it is built on the relatively new B725 action (which – along with the barrels which are back-bored, proofed for steel shot and fitted with Browning’s latest Invector DS multi-chokes – is manufactured in the Miroku factory in Japan), the B15 is assembled, stocked, smoke-lamp fitted, engraved, colour-case hardened and finished in Liege by Browning’s master craftsmen. Starting at a fraction under £10,000, it therefore sits between the Heritage Hunter (Browning’s top-end mass-produced gun which retails at around £6,000) and the B25.

Personal impressions

The first thing that struck me about the B15 Beauchamp is its good looks. The engraving (deep-scroll on the Grade E test gun) is done by hand, the oiled and hand-checkered walnut stock and fore-end are well figured and of the highest quality, and the addition of side-plates, coupled with the low profile of the B725 action, give it a sleek and elegant look.

It is available in four grades (B, C, D and E), with the latter two featuring some nice additional touches such as a skeletonised and engraved steel butt plate and steel grip cap, and a faux three-piece fore-end (mimicking that of the B25).

I had the opportunity to shoot a 30” barrelled B15 (Grade D) at clays at Atkin Grant & Lang Shooting Ground in Hertfordshire last year, and pheasants at The Glyn in Wales in December.

Now, before I share my impressions, I feel I should declare that for the past four seasons I have shot exclusively with a Browning B725 on both clays and game. And although my gun has 28” barrels and a wider sighting rib than that of the B15, it features the same action and trigger-pulls (and very similar stock dimensions) as the test gun – so I was perhaps predisposed to get along with the B15.

And I did. I love my B725 and have really gelled with it over the past two seasons in particular, but the B15 is in a different league. It has a bit more weight to it (my B725 weighs 7.25lb whereas the B15 on test weighed just under 8lb), and is well balanced with the weight slightly forward of the hands. And, as hard as this is to quantify, it just does not feel like a mass-produced gun.

On clays, I found the B15 to be both smooth and quick-handling (I tried it on a number of different targets including a fast and furious grouse sequence, some higher, straight driven clays and some long crossers). And on live game at The Glyn in Wales (one of Wayne Tuffin and Chris Lockwood’s excellent high pheasant shoots), I found the B15 a joy to shoot.

And I wasn’t the only one who was impressed; one of my fellow Guns (whose Kemens hadn’t arrived back with him in time following a service), shot the B15 on two drives and loved it. I was pegged next to him and saw him kill some sensational birds.

The B15 isn’t just stylish and elegant, it is built on an extremely strong and reliable action, and it is pleasurable to shoot. In my view, it should be on the radar of any game Shot looking for something a little bit special, but without the lengthy wait and hefty price tag of a custom-made gun.

Contact

Tel. +44 (0)1235 514550

Related Articles

Get the latest news delivered direct to your door

Subscribe to Fieldsports Journal

Elevate your experience in the field with a subscription to Fieldsports Journal, the premium publication for passionate country sports enthusiasts. This bi-monthly journal delivers unparalleled coverage of game shooting, fishing and big game across the UK and beyond.

Each issue offers a stunning collection of in-depth features, expert opinions and world-class photography, all presented in a timeless yet contemporary design.

Save 10% on shop price when you subscribe, with a choice of packages that work for you. Choose from Print & Digital or Digital only with each journal delivered directly to your door or via the app every other month, plus access to past issues with the digital back issue library.