Game shooting

Watson Bros. Gunmakers

Marcus Janssen visits Watson Bros., the last independently-owned and run London gunmaking firm, where a pioneering spirit lives on.

Would you like to appear on our site? We offer sponsored articles and advertising to put you in front of our readers. Find out more.

I wonder how many people, when asked to name as many London gunmakers as they can, would mention Watson Bros.? Despite being founded almost 150 years ago and boasting an excellent reputation for best sidelock shotguns (both over-unders and side-by-sides), I would wager at least a tenner that Alexander Armstrong and Richard Osman would give them an impressively low score on Pointless. I wonder why that is?

Well, it might have something to do with the fact that everything they produce is bespoke and made entirely by hand, so they only build 12 to 15 guns and rifles per year. It might also have something to do with the fact that they are London’s last and only independently-owned gunmakers, so they don’t have the marketing might of a multimillion-pound conglomerate behind them.

As a result, they are perhaps less prominent than their competitors. However, their Tower Bridge premises could hardly be more appropriate for a London gunmaker.

I was welcomed by Staci West who led me into a light and airy workshop where a team of highly skilled gunmakers were hard at work on a range of spectacular-looking shotguns and rifles, including a mighty 4 bore wildfowling gun.

Taken aback somewhat, I followed Staci into proprietor Michael Louca’s office, a veritable treasure trove of gunmaking, sporting paraphenalia and memorabilia. Every table, shelf, windowsill and ledge was cluttered with trinkets, gadgets, journals, books, maps, guncases and luggage, the walls were adorned with a range of taxidermy, and the floor was strewn with rugs, skins and the odd lion head. “Have a seat,” said Michael, as he cleared a number of guncases from a Chesterfield sofa. Two hours later, I was still there, listening to a man who is not only hugely passionate and knowledgeable about gunmaking, but also a vastly experienced gunmaker in his own right.

HISTORY

Watson Bros. was founded in 1875 by Thomas Watson, a gunmaker who had taken over the London premises of Durs Egg, a Swiss-born British gunmaker noted for his flintlock pistols and his company’s production of the Ferguson rifle.

Within a few years, Thomas Watson had established a reputation for producing fine smallbore shotguns for ladies and boys. In 1885, his two sons joined the firm, both of whom remained integral to the business for many years to come.

In 1935, however, the company of Stephen Grant and Joseph Lang (Grant & Lang) bought Watson Bros., and shortly thereafter, one of Thomas Watson’s sons – Arthur H. Watson – became sales director of the company. Although the company’s name was kept alive under the Grant & Lang banner, it was not until 1984 that it was once again seen above any gunmaking premises (albeit as part of an amalgamation of Charles Hellis, Frederick Beesley and Watson Bros., which was then owned by Fred Buller).

However, in 1989, Buller sold the business to its current proprietor, Michael Louca. “When I bought the company, no guns had been produced under the Watson Bros. name for about 50 years,” explains Michael. But that was about to change.

A new lease of life

More than 25 years later, the names ‘Michael Louca’ and ‘Watson Bros.’ have become inextricably linked. Indeed, anyone who knows anything about the firm will tell you that Michael Louca has made Watson Bros. what it is today, having trained his entire team of gunmakers himself.

Born in Stepney, East London, in 1961, Michael secured a gunmaking apprenticeship at James Purdey & Sons when he was 17 and remained there for the next nine years, honing his craft as an expert barrel-maker and actioner. Thereafter, he set up on his own in Canterbury, making barrels for a number of English gumakers as well as a number of private clients, which he did for the next eight years. But during this time, as his client list and reputation grew, he also started to build some new best English sidelock shotguns out of his small workshop at home.

“I was actually making guns before I had a company name,” he explains, “but I always wanted to set up on my own, so when the opportunity to acquire a well-established and highly regarded London name came about in 1989, it seemed a perfect fit.”

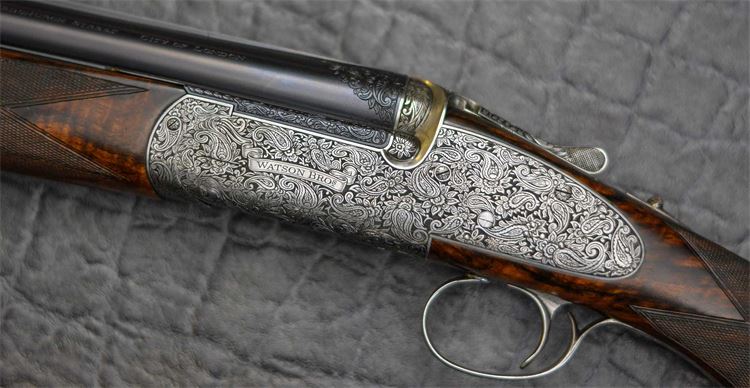

Michael’s next step was to find suitable London premises (Watson Bros. had always been based in London), and by 1990 he had set up shop in a building on Red Cross Way at London Bridge, which he rented for the next eight years (he eventually bought the building in 1998). It was from these premises that he started producing beautiful round-bodied sidelock side-by-sides with coffin-shaped backs. These distinctive-looking guns, based on the Beesley self-opening design, were the first in more than 50 years to be engraved with the Watson Bros. name. They also fitted perfectly with the company’s long-established reputation for fine, lightweight, smallbore shotguns.

“I loved the idea of taking a classic design and modernising it,” explains Michael. “And that is exactly what we did. Nowadays, a number of gunmakers make round-bodied guns, but when we launched ours, we were pretty unique in that regard.”

But Michael isn’t one for resting on his laurels – he had further ambitions to produce an equally innovative over-under as well. “I started looking at the classic Woodward and Boss designs,” he continues, “and I soon realised that I wanted to make something completely different; I wanted to make a really lightweight over-under. Everybody else’s was at least a pound more in weight than their side-by-side, and I was convinced that this wasn’t necessary.”

So, for the next two years, Michael spent countless hours behind his desk and at his workbench in his factory, often late into the night, designing, developing and refining his lightweight over-under shotgun, finally launching it in 1995.

With a brand new lightweight ejector system (which Michael designed entirely from scratch), a smaller, sleeker round-bodied action, and barrels made in-house, Michael was able to produce an over-under at the same weight as the equivalent side-by-side (i.e. 6lb 8oz for a 30″ 12 bore). “This got rid of the need to downsize to a smaller bore if one wanted a lighter gun,” adds Michael.

Breaking new ground in the British gunmaking industry is no mean feat – most gunmakers have long stopped trying in the belief that there is little or no room for improvement – but Michael has never shared that view. And his new over-under was testament to that; it genuinely offered something different to those of his main competitors’.

Of course, in recent years there has been a trend towards higher pheasants, longer barrels, bigger loads and faster, hotter cartridges, which Michael’s lightweight gun – or indeed any handmade English shotgun – was simply not designed for. So, two years ago, Michael decided to design a new ejector system and a heavier action to cope with modern cartridges. Due to the success and popularity of this new gun, all Watson Bros. over-unders are now built on this action. The 12 bore over-under action comes in three weights – light: 6lb 8oz; standard: from 6lb 13oz; and heavy: from 7¼lb (6lb 10oz being the original standard weight for a Watson Bros. 12 bore with 30″ barrels).

Made entirely by hand

Over and above his ingenuity and innovation as a gunmaker, Michael has an uncompromising and steadfast belief that the very best way to make guns and rifles is to do it by hand – entirely by hand.

“Remember, with CNC and modern machinery, you have to design the gun to suit the machining process,” he explained. “When you build a gun by hand, however, you design the gun first and then make the individual components to suit that particular design. The end result? A gun that isn’t just pretty, it is perfectly balanced and a genuine joy to use.”

With a number of full-time gunmakers – Ryan Glyde (barrel-maker), James Brown (actioner), and Bradley Topley, Richard Rumbelow (apprentices) and Alexandre Tomad (ejector work) – every Watson Bros. gun is indeed bespoke, handmade to each client’s exact specifications.

As a result, an incredible 600–700 man-hours goes into the making of each Watson Bros. shotgun (barrels: 60 hours; action: 150 hours; ejector work: 40 hours; stock: 150 hours; regulating the gun: 50 hours; polishing: 50 hours; engraving: 100 hours; finishing: 150 hours), so from order to delivery takes an average of 18 months.

Having said that, with popular combinations such as a 30″ 12 bore over-under, they will make them up to a point and have the components ready to complete within 14 months. They also carry a few new guns ready for delivery immediately (they currently have a pair of 12 bore side-by-sides, a pair of 20 bore side-by-sides and a couple of 12 bore over-unders) for clients who don’t want to wait 18 months for a new gun.

Only best sidelock guns (and a few double rifles) are produced, with every one boasting exhibition-grade wood and best hand-engraving. Michael generally uses one of five different European and British engravers to produce distinctive styles of engraving.

“I don’t think there is much point in having an in-house engraver because there is such an array of talent out there, and of course each engraver has their own style. Plus each client will have different expectations and tastes,” he adds.

Amongst the 12–15 Watson Bros. guns produced each year are one or two over-under and side-by-side double rifles. Shotguns tend to be a range of gauges, with 12 bores making up about 50 per cent of orders and the rest being a mix of 20s, 28s and .410s. In addition, they have produced a number of 4 bores.

“Regardless of the gauge, all of our guns are incredibly well balanced,” says Michael, “which comes down to the fact that we still make every component in-house, by hand, including the chopper lump barrels. This gives us complete control over every aspect of a gun’s balance and how it will feel in the hands.

“The one thing that all of our guns have in common, is that they are built to be used. And I have always firmly believed that a beautiful, well-built, perfectly balanced gun can enhance the game shooting experience.”

And for that very reason, as with anything bespoke or handmade, in order to fully appreciate their beauty, balance and craftsmanship, you’ve got to see and handle them for yourself. I’m glad I did.

Related articles

Game shooting

The Glorious Nineteenth

Rhode Island may not immediately come to mind as a prime destination for a shooting trip, but The Preserve Sporting Club and Resort is changing that perception.

By Time Well Spent

Game shooting

Lunar escape

Likened by some to shooting on the moon, Morocco’s El Koudia is full of adventure, unique experiences and an abundance of terrain that you simply won’t find elsewhere

By Time Well Spent

Get the latest news delivered direct to your door

Subscribe to Fieldsports Journal

Elevate your experience in the field with a subscription to Fieldsports Journal, the premium publication for passionate country sports enthusiasts. This bi-monthly journal delivers unparalleled coverage of game shooting, fishing and big game across the UK and beyond.

Each issue offers a stunning collection of in-depth features, expert opinions and world-class photography, all presented in a timeless yet contemporary design.

Save 10% on shop price when you subscribe, with a choice of packages that work for you. Choose from Print & Digital or Digital only with each journal delivered directly to your door or via the app every other month, plus access to past issues with the digital back issue library.

Manage Consent

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.

Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.

Statistics

The technical storage or access that is used exclusively for statistical purposes.

The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.

Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.